Technical description climbing walls

Our company, Makak climbing s.r.o., has built over 35,000 m2 of climbing walls of various types for several hundred satisfied customers, from small simple walls for beginners to walls in training centres designed for training and professional competitions. Starting from the initial contact, our company makes an effort to efficiently combine the customer's idea, space capacities and functional requirements so as to produce the optimum design of a climbing wall for the specific situation.

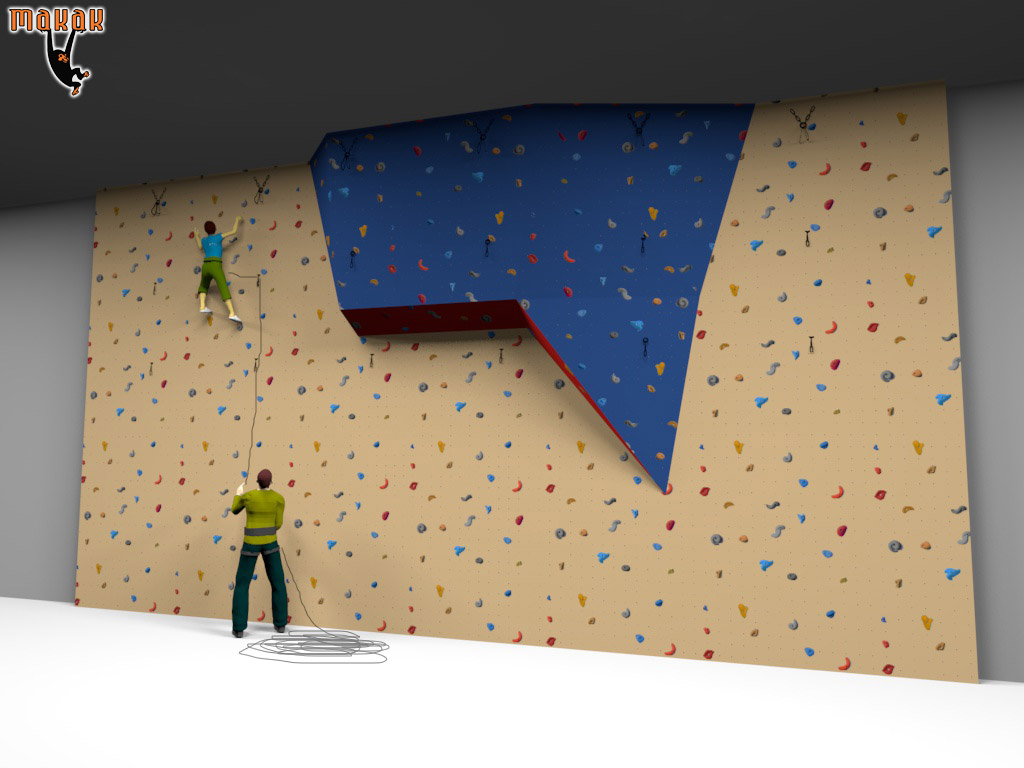

Artificial climbing wall

The climbing wall facing shape design is made using the Cinema 4D software.

The static calculation for the internal framework and the climbing wall stability calculation are performed using the Feet 2000 software using the finite element method. The calculation is performed according to the European standard ČSN EN 12572-1:2007 and ČSN EN 12572-2:2009 (hereinafter EN). The calculation takes into consideration the rigidity of the elements and the rigidity of the joints (bolted or welded joints). The framework is modelled as a spatial bar framework with a customised anchoring method (existing wall, foundation footings, etc.). A verification test is carried out for each climbing wall (pursuant to EN) after which the customer is given a Declaration of Conformity, the static calculation and the recommended instructions for use.

Technical description

Supporting structures

In most cases, the supporting structure consists of welded or assembled steel truss girders designed by the static calculation. The surface finish of the steel structures is three layers of corrosion prevention paint by default. For outdoor use, the structures can be hot galvanised by arrangement. The steel supporting structures are manufactured from 10235 grade steel. Steel structures are anchored depending on existing structural capacities and in accordance with the static calculation (HILTI chemical mortars, M12 heavy-duty threaded rods, etc.).

The steel supporting structures are complemented with 80x80 mm wooden balks. The timber is coated with protective paint (Lignofix) for outdoor use.

The laminated facing is fastened to the steel frame directly using shaped metal plates located in panel corners, or wooden balks if the facing is made of wood. Bolts and screws are used as the jointing material. SI grade timber is used for the wooden balks. Wood-only frames are used for simple climbing and bouldering walls.

Layout and distribution of personal securing points: the securing points are installed using rivets (made by Fixe). The design for installation of personal securing points and equipment of personal overhead securing is made in accordance with EN. The strength of the personal securing points is calculated to be 10.0 kN (1000 kg) and tested for 8 kN (800 kg) after the climbing wall is completed. Each marked direction is terminated by an end chain attached in two points. There are two steel carabiners installed in each end chain.

Wall facing

Wooden: The facing is made of birch plywood 18 mm thick, formatted to 1510x1510 mm or 2500x1250 mm. Water-resistant plywood is used for outdoor installation. The climbing wall surface can be designed using variously warped or deformed profiles with crack and layback elements. Larger shapes are jointed together using balks or plywood strips and screws.

By default, the panels have various surface finish treatment to provide roughness, but they can also be smooth. The panels, and the complete wall, are coated with two-component epoxy paint. One coat is the base paint, the other coat (once the climbing wall facing is complete) is in selected shades according to the RAL system.

Plywood facing

Plywood facing Laminated facing

Laminated facingThe panels are coated on the reverse as well for outdoor use. The density of T-nuts for installing climbing holds is 50 per m2 as a rule; more upon customer request. We offer stainless steel nuts for outdoor use, and galvanised for indoor use. The nuts are fastened using 2 screws on the wall reverse. This prevents the nut from becoming loose or dropping out of the panel during use (see Figure T-nuts).

T-nuts

T-nutsPanel joints where rope friction is expected are fitted with protective metal bars fastened with countersunk screws.

Laminated: The facing is composed of profiled modular panels 8-12 mm thick in various shapes, permitting an easy wall (recumbent) or a severely overhanging one. The wall facing can be manufactured in any colour scheme. Each modular panel 1000x1000 mm has 8-12 places for installation of climbing holds. The advantages of this facing type are its long life, resistance to climate and easy maintenance.

Freeform: The shape and surface finish of the facing is a true imitation of a rock surface. Like the laminated facing, it is hand-made from glass fibres and polyester resin.

Unlike with laminated facing, however, it is not restricted to the shapes of square panels, meaning that various "tailor-made" climbing profiles can be created.

By default, the surface offers 12-16 inserts per m2 for installing climbing holds.

Again, the advantages of this facing type is its longer life, resistance to climate and easy maintenance.

Freeform facing

Freeform facing Freeform facing

Freeform facingBy arrangement, holes for lights or air conditioning can be made in the facing. Windows can be covered using PC Makrolife 15 mm thick with drilled holes for installing holds.

All the climbing wall facing types offered are certified pursuant to ČSN EN 12572-1:2007

Polycarbonate: This surface is made of full 15 mm clear PC. In this way we can also cover windows while keeping the daylight. The panels are threaded for fixing the climbing holds.

Tilting systems

Using tilting systems we can easily change the tilt of the individual profiles and so affect the difficulty of climbing.

Manual: Manual tilting system profiles uses manual chain hoists. The system is suitable for bouldering walls. The tilting angle - overhanging may be 0° to 40°.

Hydraulic: Hydraulic systems allow tilting of whole sections of climbing walls. The angles of inclination may be in the range of -50° to 50°.

Manual and hydraulic tilting systems

Holds and Volumes

The wall can be fitted with up to five hundred climbing holds of various sizes, shapes and colours from our catalogue.

We recommend at least 5 holds per m2 for climbing walls (8 per m2 for bouldering walls), fastened in the T-nuts on the obverse of the wall using bolts. We recommend stainless steel nuts and bolts for outdoor use, and galvanised for indoor use.

The holds are certified pursuant to ČSN EN 12572-3:2009. The different hold colours then constitute multiple climbing paths of any difficulty in one part of a wall.

Climbing wall are not included in the basic budget.

Upon customer request, the wall can be fitted with a landing area 12-40 cm thick or the full required climbing materials (quickdraws for rivets for progressive climbing, ropes, seats, securing equipment, climbing footwear, etc.). We supply products of Rock Empire, Fixe, Petzl, Tendon, La Sportiva, etc.

Price

Our price includes all costs associated with the production and climbing wall installation and is final.

The price includes:

- climbing wall design

- climbing wall construction project

- steel structure manufacturing and installation

- wall facing manufacturing and installation

- paint coats

- installation of securing points

- installation of end chains

- verification test

- accommodation

- we provide a 60-month warranty period on supplied walls

Based on your documentation and information we can provide you visualizations and a budget for free. Contact us.

You can find a part of our realized projects in our Galery.